Hello laser enthusiasts,

I regularly use a FabKit Mk6 we bought last year at work (at a French scientific public institute).

It took us few months to assemble and have it work reliably because we did not had much time to work on it at first.

The last thing we had to adjust was a loose pulley on the Y-axis motor and then it worked really great (controlled directly using LightBurn through USB cable) with good match between cutting work and engraving work (using the presets found on this precious forum).

Since last week, I noticed deviation along the engraving areas showing as an inconsistency in X coordinates as shown in the following image:

On this photo you can see one path and an half engraving on cardboard (engraving at 400mm/s starting at the bottom of the area with a height roughly of 5cm).

The two passes aren’t overlapping as the first one was slopped (curved) but the second (stopped on purpose) was correct.

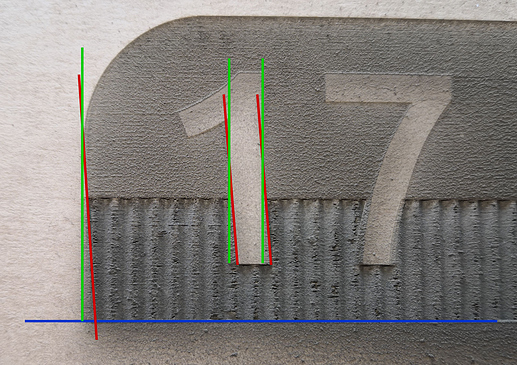

On the following image I added coloured lines to help explain the problem:

Colour line description:

- blue: horizontal reference

- red: slopped first pass

- green: vertical (and correctly positioned) second pass

The first horizontal engraved line pass seems to start 2mm right of what it should have been and with each new horizontal engraved lines, this offset seems to fade.

The problem is the same at the other side of the engraved area with the first engraved lines finishing 2mm right of the correct position.

The belt tension responsible of the X-axis movements seems to be ok. It is not too strong as if to much screw-turns are applied to adjust it, the 90° bent metal part starts to change its right angled shape.

Is any of you have an idea of what can possibly be the origin of this problem (and maybe how to correct it)?

Thank you.

Hi Cyprien,

It might be to do with https://docs.lightburnsoftware.com/ScanningOffsetAdjustment.html

Did you enter the values from the manual? 500mm/s is the normal one for engraving.

400mm/s will try and guess the value.

If the belts are fine, it could be a grub screw on the X axis motor is a little loss and allowing slight movement when its changing direction.

Hi Bonne, thank you for your answer.

The Offset adjustment values were set using values found on the FabCommunity forum (from 100 to 500) and were working well and with an offset problem, the error is visible for all the engraving and not “changing” during the engraving procedure.

In the meantime, we noticed a new “weird noise” when the X axis was reaching the left part of the rail (strong vibrations ringing in the moving part bearing the focal lens).

There was less noise when the belt was loosen but wasn’t really a solution.

When we disassembled the left X-axis pulley, we noticed some play between the screw and the pulley, and also a bend at the end of the screw.

The output perimeters of the pulley threaded hole was also rough with raised aluminium shards.

We changed the screw and deburred the threaded hole of the pulley and the noise disappeared.

Also with a less tight belt as it was at the beginning, the problem of “slopped engraving” seems to have vanished.

I think the loose pulley on the screw added a bit of play in the head movement who eventually tighten during the engraving process and the noise maybe was coming from the bend screw and the aluminium shards.

I need to run more tests to confirm it and verify the grub screw you mentioned.

Thank you again,I will keep you in touch shortly.

I verified the grub screw on the X axis motor pulley and it was loose enough to let it rotate few degrees.

We had the same problem with the Y axis few months ago but the symptoms were different enough for me not to relate.

Thank you again for your time and knowledge!

1 Like